Environmental Control House (E.C)

Modern poultry houses are built with a sophisticated environmental controlled system which is mainly associated with keeping the broilers safe and satisfied from exterior weather and other harms, During hot weathers inside conditions are maintained as near as to the bird’s optimum requirements.

Temperature, Ventilation, Air flow speed, Relative humidity are all system controlled with fail safe manual controls. Feeding system and watering system are all mechanized and automatic. All of the above has separate alarm systems and backups in case of malfunctions.

- Temperature:24°C

- Relative Humidity - 50 to 60%

- Ammonia ( < 25ppm), Carbon dioxide ( < 5000ppm), carbon monoxide ( < 50ppm) and dust levels are kept to minimum.

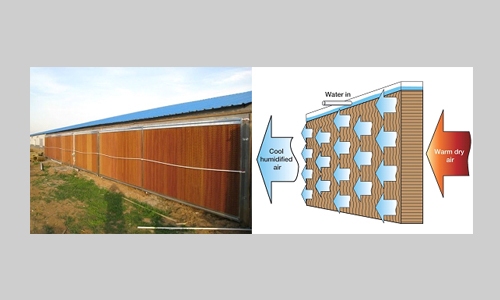

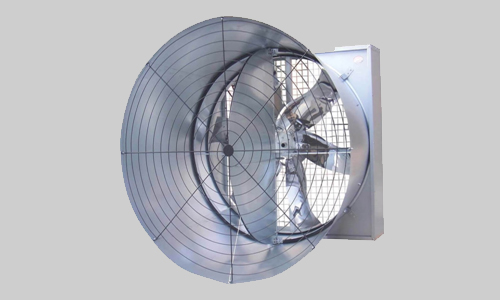

A closed building with No windows, longitudinal preferably east to west, with High Performance exhaust cone fans on the east side while evaporative cooling pads on the west side along with automatic feeding and drinking systems inside.

ECTS helps to achieve better FCR, improving production and care of birds, controlled is eases and meets other safe growing conditions.

| Design and structure | Conventional Open Shed(COS) | Environmental Controlled Tunnel Shed(ECTS) |

|---|---|---|

| Outlook |

Monitor type roofing Open side elevated Lumber on concrete columns wooden trusses |

Closed housing Not elevated Concrete floor Side walls with windows and thermal insulation steel trusses |

| Micro-climate control |

No direct control Curtain management Difficult to control the Temperature, relative humidity and Air flow rate (ventilation) |

Directly controlled by electronic sensors Use cooling pads and exhaust fans to control microclimate Easy to control the Temperature, relative humidity and Air flow rate (ventilation) |

| Feeding system | Trough and Tube feeders | In-line automatic feeders |

| Watering system | Gallon and bell waters | In-line automatic nipple drinkers |

| Brooding set-up | Pot with Charcoal or Electric heater with cocopeat and Paper | High efficient Gas heater |

| Floor | Elevated-slatted floor. Uses wood or bamboo slats allows minimum 1.25sq.ft floor space per bird | Plastic slat floor overlaid or ground concrete floor Allows minimum 0.65sq.ft floor space per bird |

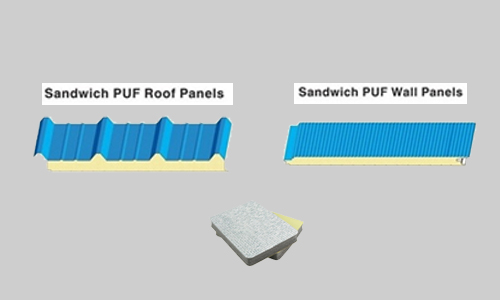

| Roofing system | Corrugated GI sheets monitor-type without insulation | Corrugated GI sheets with thermal insulated housing |

| Factors | Conventional Open shed | Environment Controlled Tunnel shed |

|---|---|---|

| Birds Placement | Birds placement density is low, which is 0.8sq.ft/birds or 1.25sq.ft/birds | Birds placement density is high, which is 1.54sq.ft/birds or 0.65sq.ft/bird |

| Production Cost | Production cost is high | Production cost is low |

| Production Capacity | Production capacity is low | Production capacity is high |

| Manpower requirement | Requires more human labour involvement for feeding and watering for birds | Requires very minimum labour all the feeding and watering are controlled by automatic control system |

| Micro Temperature Control | Maintaining even Temperature is almost impossible | Maintaining even Temperature is very easy and very accurate |

| Biological management | Infection controlled rate is less | Infection controlled rate is high |

| Number of batches /cycles per year | Due to severe heat stress during 4 long summer months, in some cases the broiler production is stopped resulting in only 4-5 batches per year. Maximum batches per year could be 6 | 7 batches are easily possible. Maximum of 8 batches can be achieved in this case |

| Cost of Vaccine and medication | The COS are prone to diseases and heat strokes. Vaccine and medication can reach up to Rs.5 per bird | The ECTS being completely closed system has a very minimized incidence of diseases cutting down the vaccine and medication cost to less than Rs.1 per bird |

| Bird Mortality | 5% - 10% | 2% - 3% |

| Uniformity in bird weight | Unequal distribution of feed and water to broilers, which gives 75% uniformity in bird weight. | Equal distribution of feed and water to broilers gives an amazing uniformity of 95% in bird weight. |

| FCR | 1.6 to 1.9 | 1.40 to 1.55 provides the best FCR results which in turn gives highest profit |

Project Description

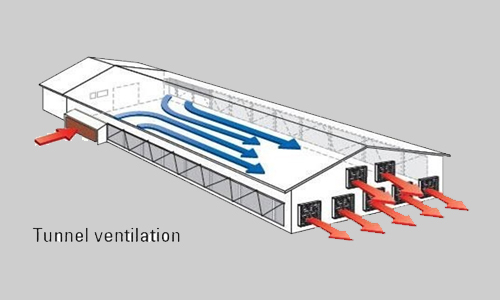

Tunnel Ventilation

Most effective in tropical climate due to higher air exchange rate & faster air movement @2.5 - 3m/sec. Fresh air enters the house at one end and pulled through the house in longitudinal direction at the other end.

Main goal of Tunnel ventilation is to provide cooling effect of birds. It helps to maintain end to end temperature difference as low as possible. Low humidity during extreme hot and humid weather. To get rid of immense heat dissipated by the bird sand to obtain wind chill effect as per requirement of the birds.